- المنتجات المعدنية منتجات الألومنيوم منتجات النحاس المنتجات المطلية بالمعادن المنتجات الفولاذية المقاومة للصدأ منتجات الفولاذ الكربوني خلط المعادن الخاص

- المشاريع لوحة الحواجز الفولاذية رف الخزانة الهياكل الفولاذية الجسر الفولاذي السقالة المواد الإنشائية المواد الخام الكيميائية One Stop Solutions for Projects

- الحاويات الحاويات القياسية لـ ISO الحاويات للمعدات الحاويات للتخزين والنقل دار الحاويات الحاويات المثلجة الحاويات القريبة السواحل

- الماكينات آلة تشكيل المعادن الآلات الأخرى آلة قطع المعادن آلة تصنيع المعادن آلة التعويج آلة تصنيع البلاط

- منتجات الماكينات صناعة السيارات المنوعات معدات الإرساء معدات السفينة أناء الضغط

- النظام الكهرباء والميكانيكي الكابل الكهربائي الأوتوماتيكي التنسيق الكهربائي نظام طاقة الشمس نظام حماية أمن الكهرباء آلة التحويل خط الأنتاج نظام الإضاءة

- المعدات الطبية منتجات الإطعام منتجات أنبوب إدخال القصبة الهوائية منتجات الرعاية المنتجات البلاسبيكية

- epc مشاريع

- آلات البناء

- خط أنابيب النفط

- خط أنابيب المياه

- انبوب الغاز

- مستلزمات السفن والرباط

- المعادن للزخرفة/ للديكور

- مكونات المحولات

- أنابيب التبادل الحراري

- قطع غيار تكييف الهواء ومستلزماته

- سخان مياه

- أدوات المطبخ و الحمام

- المعادن للأجهزة المنزلية

- أجهزة الطاقة الشمسية

- المصعد الكهربائي

- الأسطح والأسقف

- الكابلات

- الخزانات

- التعبئة والتغليف

- قطع غيار الآلات والمعدات ومستلزماته

- القوالب

- قطع غيار السيارات

- السكك الحديدية و رافعات السكك الحديدية

- تركيب الأجهزة

- الكاشطة

- معدات بناء الطرق

- المكونات الإلكترونية

- اعمال البناء ومواد الديكور

- الأبواب والنوافذ

- الثلاجات

شريط فولاذي مقاوم للصدأ للرقائق المعدنية المسكوكة

:مواصفات الاشرطة الفولاذية المقاومة للصدأ للرقائق المعدنية المسكوكة

ASTM A240, JIS G4304, G4305, GB/T 4237, GB/T 8165:المعايير

الفئة:سلسلات200,سلسلات300,سلسلات400

السماكة:0.1ملم-3.0ملم

العرض:3.2ملم-550ملم

الطول:على حسب العميل

6K, 8K,2B, BA,الملمس الخارجي:طلية نهائية صقلية,ذات الخطوط الرفيعة ,الصقل الغير لامع

تقنية المعالجة:الدلفنة على البارد/الدلفنة على الحار/السحب على البارد

Specifications of Stainless Steel Strip for Metal Stamping:

1. Standard: ASTM A240, JIS G4304, G4305, GB/T 4237, GB/T 8165

2. Grade: 200series&300series&400series

3. Thickness: 0.05mm - 3.0mm

4. Width: 3.2mm-550mm

5. Length: as customers' request

6. Surface finish: 2B, BA, Mirror finished, N04, Hair Line, Matt finished, 6K, 8K

7. Manufacture technology: cold drawn/cold rolled/hot rolled

:إنتاج الشريط الفولاذي المقاوم للصدأ

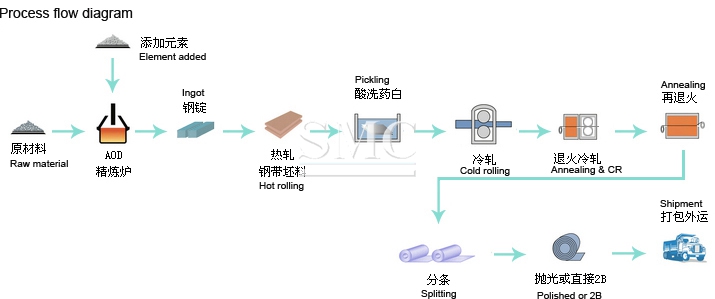

الشريط الفولاذي المقاوم للصدأ المدرفلة على البارد هو عبارة عن منتجات شبه منتهية التصنيع تم الحصول عليها من الالواح والكتل المعدنية المدرفلة على الحار,بينما يتم إنتاجها عن طريق الدرفلة على البارد

الاشرطة الفولاذية المقاومة للصدأ المدرفلة على البارد يتم إنتاجها من خلال الدرفلة على الحار,الثني,الصقل بالحامض وذلك من خلال دلفنتها بالبارد في إسطوانات الصقل.يتوقف ذلك على السماكة المطلوبة

تتطلب الدرفلة على البارد ان تمر عدة مرات على مطاحن الدرفلة لتعطي الإختزال المطلوب ممايضمن الخصائص والمميزات الميكانيكية المرغوب فيها

:المعلومات المتعلقة بحزمة الشريط الفولاذي المقاوم للصدأ

150mm - 610mm:معرّف اللفافة

300mm - 1200mm :القطر الخارجي

أصغر كمية للإختبار5 طن عن كل سماكة.1×20 عن كل ترحيل

تحزم منتجاتنا وفق للأنظمة والمعايير العالمية وبما يتوافق مع متطلبات العميل .سوف نبذل قصارى جهدنا لتفادي أي ضرر قد يلحق بها خلال عمليتي التخزين والترحيل

:FAQ

هل انتم شركة تجارة أو منتجين؟:Q

نحن منتجين.نحن نستطيع القيام بعمليات أكثر مثل الصقل ,مدور الحواف والخ.وما بعد التقطيع:A

هل يمكنكم إمدادنا بعينات؟:Q

نعم ,بكل سرور اذا كان لدينا في المخازن

ماهو نطاق عرض القطع لديكم؟:Q

يتوقف ذلك على سماكة أشرطةالفولاذ المقاومة للصدأ,عادة يكون أقصى عرض قطع هو 650 ملم وأقل عرص 5 ملم أو أقل:A

من أين تاتيكم المواد الخام؟:Q

,والخBAOSTEEL, TISCO, POSCO, JISCO

ما هي معايرك للحزم؟ :Q

معاييرنا للحزم هي ورق مقاوم للماء مع لاصقات تحزم في حاويات أو صناديق خشبية إذا كانت لفات صغيرة:A

FAQ

Q: Are you a trade company or manufacturer?

A: We’re a manufacturer. We can do more processings like polished, round edge etc. after slitting.

Q: Can you provide free sample?

A: Yes, we can if there’re some in stock.

Q: Where is your raw material from?

A: BAOSTEEL, TISCO, POSCO, JISCO etc.

Q: What’s your range of slitting width?

A: It depends on thickness of stainless steel strip. Regularly the max. slitting width is 650mm and the min. is 5mm or less.

Q: What’s your standard package?

A: Our standard package is waterproof paper with wraps, packed on a pallet or in a wooden package if it’s small coil.

هنا

ل

السعر

سوف نتصل بك في غضون 8 ساعات